Fuel cells are emerging as a powerful solution for clean and efficient power generation. They produce electricity with water as the only by-product, making them ideal for decarbonized transportation, stationary power, and portable energy systems.

To prepare engineers and researchers for this growing sector, institutions are investing in Fuel Cell Laboratories—specialized facilities that bridge classroom theory with real-world practice. These labs support hands-on learning, innovation, and technical skill development in hydrogen and electrochemical energy systems.

Defining the Objective of a Fuel Cell Lab

Every successful fuel cell lab setup begins with a clear purpose. The lab may be built for academic instruction, applied research, or industrial training.

For universities, the focus is on helping students explore electrochemical reactions, efficiency, and cell design. For industries, the objective may be to test new materials, catalysts, or reformer technologies.

Having well-defined goals ensures that the laboratory’s layout, instrumentation, and safety systems align with both educational and research outcomes.

Core Components of a Fuel Cell Laboratory Setup

A comprehensive fuel cell laboratory integrates multiple systems that collectively demonstrate hydrogen-based energy conversion.

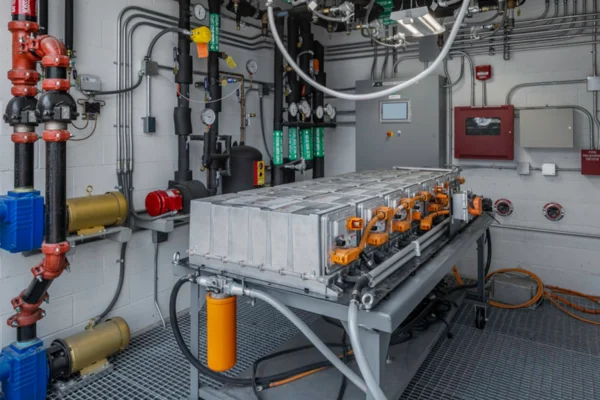

1. Fuel Cell Stack Module

The fuel cell stack is the centerpiece. It demonstrates how hydrogen and oxygen combine to generate electricity. Depending on the focus area, the stack may be PEM (Proton Exchange Membrane) or Alkaline type. Students can measure output voltage, current density, and overall cell efficiency under different conditions.

2. Gas Supply and Flow Control System

Hydrogen and oxygen are supplied through precise flow controllers, pressure regulators, and humidifiers. Filters and purge valves maintain safe and stable operation while allowing experimentation with humidity and gas flow parameters.

3. Hydrogen Generation and Storage Unit

To make the setup self-contained, labs often integrate electrolyzers that generate hydrogen from water. The produced gas is stored in metal hydride or composite cylinders for later use. Including both PEM and Alkaline electrolyzers allows comparative study and enhances the versatility of the hydrogen lab.

4. Power Conditioning and Load Section

The DC power generated by the stack passes through converters or inverters for analysis. A programmable electronic load helps test performance under various load conditions and observe efficiency behavior during dynamic operation.

5. Sensors and Data Acquisition System (DAQ)

An intelligent DAQ system forms the analytical core of the fuel cell research lab. Sensors capture temperature, voltage, current, and pressure data in real time. Digital dashboards visualize trends, enabling performance evaluation and troubleshooting.

6. Control and Safety Interface

Safety is non-negotiable in any fuel cell laboratory setup. The system must include hydrogen detectors, flame sensors, emergency shutdown valves, and automatic alarm systems. These ensure secure operation and give learners the confidence to conduct experiments safely.

Setting Up the Laboratory Space

The physical layout of the fuel cell training lab should balance safety and accessibility. Hydrogen, being odorless and lighter than air, demands a well-ventilated and monitored environment.

Workbenches should allow free movement and clear visibility of each subsystem. Install electrical isolation, grounding, and gas leak detection systems that comply with international safety standards.

A modular lab layout is recommended, allowing future expansion with hybrid setups like hydrogen-battery integration or renewable-powered electrolysis.

Integration with Academic Curriculum

Introducing a fuel cell lab within engineering programs helps students link theoretical knowledge with practical application.

Through structured experiments, learners can plot polarization curves, analyze stack efficiency, and measure heat and mass transfer effects. Integrating hydrogen generation, storage, and utilization modules ensures interdisciplinary learning across electrical, chemical, and mechanical domains.

Such practical exposure builds industry-relevant skills and prepares graduates for roles in the fast-growing hydrogen and fuel cell sector.

Industrial Training and Skill Development

The scope of fuel cell technology extends far beyond classrooms. Many industries now use similar labs for employee training and upskilling.

Professionals can test hybrid configurations combining fuel cells with batteries or supercapacitors, study degradation patterns, and optimize performance parameters.

According to BloombergNEF, global hydrogen demand could increase fivefold by 2050. This highlights the urgent need for skilled talent capable of designing, testing, and maintaining hydrogen-based systems.

Safety and Compliance Considerations

Working with hydrogen requires strict adherence to international standards such as ISO 14687 (hydrogen purity) and IEC 62282 (fuel cell systems).

Essential safety measures include:

- Installing hydrogen, flame, and ultrasonic leak detectors

- Ensuring adequate ventilation and flame-proof electrical fittings

- Using automatic gas shut-off valves and audible alarms

- Providing PPE and regular safety drills

- Performing periodic inspections and sensor calibrations

A strong safety framework is key to long-term operational reliability and user confidence.

Encouraging Research and Innovation

Beyond teaching, a fuel cell research lab promotes innovation. Researchers can explore new catalysts, membranes, and control strategies to improve performance and reduce costs.

Collaboration between academia and industry can foster breakthroughs in green hydrogen systems, accelerating the commercialization of clean energy technologies.

Such partnerships transform a simple training setup into a center of excellence for sustainable energy innovation.

Conclusion

Setting up a Fuel Cell Lab is more than an academic initiative—it’s an investment in future-ready talent and technological progress.

By combining modular design, real-time monitoring, and strong safety protocols, institutions can create impactful training and research environments.

A well-planned fuel cell laboratory setup prepares engineers to lead the hydrogen transition, transforming theory into practical solutions for a cleaner, more resilient energy future.