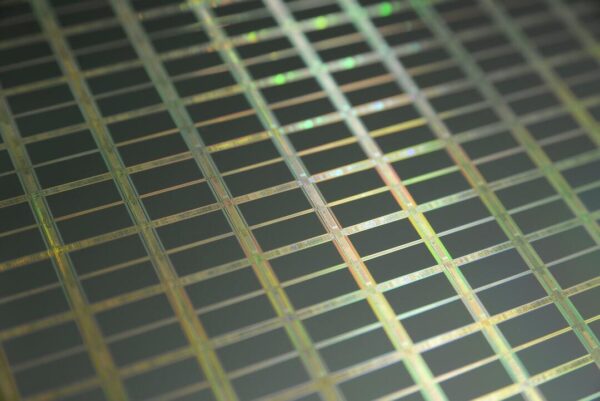

The world of electronics is always changing, and one key part of this is semiconductor wafer manufacturing. New ideas and better tools are improving how chips are made. If you want to understand what’s shaping the future, now is a good time to learn.

Below are the top trends making an impact in this space. From better materials to smart automation, these changes are big.

Keep reading to see what’s coming next.

Smaller Node Sizes Becoming Standard

The push for smaller chips continues to grow. Making wafers with tiny node sizes is now more common. This helps make devices faster and more efficient. It also lowers energy use in electronics.

As tools improve, the industry can go even smaller. These changes help build better phones and computers. Smaller nodes also mean more chips per wafer. This makes the process cheaper in the long run. More firms are moving toward this trend now.

More Use of AI in Manufacturing

Artificial intelligence is now used in wafer production. AI helps spot problems early. It can also predict issues before they happen. This reduces waste and saves money. AI tools also improve quality checks.

Smart systems make things move faster. They learn from data to keep improving. This trend will keep growing. It brings many benefits to factories.

Advanced Lithography Techniques

New lithography methods are now in use. These tools can make very fine patterns. They help place features on wafers more precisely. This leads to better chip performance.

It also supports smaller nodes. These machines need less space to work. This cuts down on costs. More companies are switching to these tools. They offer long-term value.

Wafer Thinning for Better Results

Thinner wafers help reduce heat. They also make chips lighter. This is great for mobile devices. Wafer thinning also supports new chip designs.

The process has become more stable. It allows for more compact builds. Fewer layers mean better cooling. The demand for thinner wafers is rising. It’s a key step in modern production.

Growth in 3D Chip Stacking

3D stacking places chips on top of each other. This saves space and boosts performance. It also helps devices run faster. Heat control is better with this setup.

It allows more functions in one chip. Tools for stacking are now more advanced. Many companies see value in this method. It’s growing fast in the market. This trend will likely continue.

Eco-Friendly Manufacturing Practices

Factories now focus on green practices. They use less water and energy. Recycling is also more common. These steps help the planet. Better filters cut down on waste.

New systems use cleaner materials. The goal is to reduce harm to the earth. More rules also push for this change. It’s becoming a key part of production.

Rise of Compound Semiconductors

Not all chips use the same base. Compound materials are now more popular. They handle heat better. These materials also work at higher speeds. They are great for power devices.

More research is going into this area. These semiconductors cost more but perform better. They suit special uses. Expect to see more of them soon.

Shift to Larger Wafer Sizes

Wafers now come in bigger sizes. This means more chips per wafer. It helps lower costs. Production time is also better. Machines can handle larger wafers now. These tools are more common.

Making more chips at once saves effort. Silicon wafers in larger sizes are now widely used. It’s a trend that improves output.

Automation in Cleanrooms

Robots now help in cleanrooms. They reduce human error. This keeps wafers safe from dust. Robots also work faster. They help move items between steps.

This cuts down on delays. Machines can also run longer. Fewer workers are needed for some tasks. It makes the process smoother.

Focus on Yield Improvement

More effort now goes into yield. Better yield means fewer broken chips. This saves money and time. New checks are added at each step.

Better sensors also help. Smart tools can catch issues early. This avoids waste later on. Teams look at data to find patterns. This trend is key for profits.

Use of Smart Sensors in Production

Sensors are used to track many things. They measure heat, pressure, and movement. This helps spot issues early. It also makes fixes faster.

Sensors send data to main systems. These systems learn over time. Smart tools adjust on their own. This boosts quality. More factories are using them now.

Flexible and Stretchable Electronics

New types of chips can bend. These are good for wearables. They can also go in medical tools. Making flexible chips needs new steps.

Special wafers are used for this. These chips must still work well. Heat and pressure must be managed. These products are gaining interest. More research is being done.

Edge Computing Driving New Designs

Edge tech needs fast chips. These chips must be small and smart. They must also use less power. Wafer makers are changing designs.

New layouts help with this need. It’s important for smart devices. Cities and homes use edge tools. The trend shapes how chips are made. It’s growing with time.

Improved Defect Detection Systems

Detecting defects early is now a key focus. New systems use cameras and sensors to scan wafers. They can find tiny flaws that were once missed. This helps avoid bad chips later in the process.

Better checks mean less waste. These tools also learn over time. They adjust to spot new kinds of issues. The goal is to catch problems before they spread. Many factories are now using these systems more.

Integration of Photonics in Wafer Design

Photonics is becoming part of chip design. Light is used instead of just electricity. This makes data move faster on a chip. It also reduces heat in some parts. Wafer processes now include new steps for this.

Special layers help guide the light paths. These chips work well for high-speed data. More labs are testing these designs. It’s a growing part of the industry.

Discover the Top Trends in Semiconductor Wafer Manufacturing

Semiconductor wafer manufacturing keeps evolving. These trends help make better, faster, and greener chips. With new tools and methods, the future looks strong. Keeping up with these changes is important for anyone in the tech field.

As demand grows, so will innovation. The industry moves fast, but these trends give direction. Whether you build chips or use them, this matters. It’s a good time to watch and learn. More changes are surely ahead.

Check out more reads on our blog.