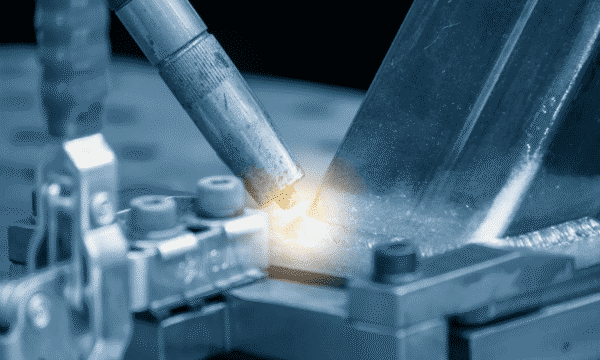

Welding has always been connected to heat, sparks, and large, heavy equipment. Laser welding has changed everything. It provides a clear, accurate, and very adaptable substitute. Laser welding uses a concentrated light beam to melt and fuse materials. It produces clean, strong welds with no thermal distortion. It is unlike traditional welding methods. This innovative technology opens up opportunities. It is an invaluable resource for various sectors.

Shining on Different Materials

The unparalleled material compatibility of laser welding is one of its distinguishing characteristics. Laser welding is an effective way to join various metals. It can also join polymers and even dissimilar materials. It can combine sensitive electronics and automobile components. It can also combine durable aerospace structures and medical implants. Its adaptability reduces the need for various welding procedures, which speeds up production.

● Metals

Laser welding handles a variety of metalwork with ease. It can weld mild steel, aluminum, and even exotic alloys like titanium and nickel. Choose one you prefer.

● Plastics

Laser welding produces exact and hermetic seals. It works on various plastic types. These include complex medical devices and automotive components.

● Dissimilar Materials

Laser welding can join dissimilar materials. For example, metal and plastic, metal and glass, or dissimilar metals. It used to be considered impossible to join them.

Scaling Up and Down

Laser welding can handle various materials, from massive steel plates to micrometer-thin wires. The laser is suitable for large-scale building projects and delicate microelectronics. This is because it offers fine control over the concentrated beam. It enables welding on various thicknesses and geometries. This versatility demonstrates the technology’s wide range of uses. For example, it can combine complex jewelry components and weld large ship hulls.

Getting to Tight Spots

Forget about large welding torches that have trouble getting at odd angles. You can easily fit a concentrated beam of a laser welding machine through tiny openings. It can also fit through complex shapes. It makes applications like minor electronics repair possible. It also makes welding inside hard-to-reach vehicle components possible. Imagine effortlessly connecting intricately designed medical devices. Or fixing a malfunctioning connection deep within a circuit board.

Speed on Your Side

Money is measured in hours, and laser welding recognizes this. Laser welding enables much faster processing speeds than previous technologies. This increases production efficiency and decreases overall fabrication time. This works exceptionally well in high-volume production settings. Quick processing leads to higher output and quicker product delivery.

Cleanliness Counts

Laser welding is valuable in sectors where accuracy and hygienic practices are critical. Laser welding is different from alternative techniques. They produce fumes, sparks, and spatter. In contrast, laser welding provides a sterile and controlled procedure. This makes it perfect for applications like assembling electronics and manufacturing medical devices. It decreases post-weld cleaning and lowers the danger of contamination.

Beyond Welding

Beyond welding, laser technology is incredibly versatile. The same laser system can be used for marking, cutting, and cladding. Only minor alterations are needed. It provides a multipurpose solution for various manufacturing requirements. As a result, specialized equipment is no longer required for every task. This streamlines operations and maximizes resource use.

● Manufacturing

Laser welding guarantees strength, accuracy, and rapid production speed. It is used for everything from electronics and automobile parts. It is also used for medical devices and aerospace components.

● Jewelry

Fine jewelry needs to be welded with accuracy and aesthetic appeal. Laser welding produces perfect seams. Unmatched control makes this possible. The seams highlight the design’s brilliance.

●Electronics

The need to make electronics smaller necessitates the careful welding of small components. Laser technology shines in this area. It makes it possible to design intricate circuits and gadgets.

●Medical

Laser welding is crucial for making medical devices like implants and stents. Its accuracy guarantees functionality and biocompatibility.

Automation Advantage

More potential is unlocked by combining robotics and laser welding. The combination minimizes human error. It provides accurate, automated welding, perfect for high-volume production. It is especially useful in repetitive jobs, such as vehicle manufacture. Robotic laser welding guarantees uniform, high-quality welds.

Sustainability in Sight

Laser welding is becoming a more sustainable option. Environmental concerns are rising. Low waste production and economical energy use make manufacturing more environmentally friendly. Businesses are looking to lessen their environmental impact. And contribute to a more sustainable future will find resonance in this.

The Future Is Bright

Laser welding has a bright future because of ongoing developments in laser technology. The possibilities are endless. They range from enhanced automation to AI integration. They also include increased power and beam control. It opens up new uses for laser welding and solidifies its value for many industries.

Conclusion

In summary, laser welding sheds light on adaptability, accuracy, and productivity. Its versatility in handling different materials, maneuvering in confined locations, and providing efficient, fast processing. That makes it an invaluable tool for many businesses. The future of laser welding seems even more promising as technology advances. This further cements its role as a game-changing force in the manufacturing industry.