Precision dispensing sits at the heart of modern aerospace manufacturing, where consistency, repeatability, and material control directly influence structural integrity and long-term performance. From bonding composite panels to sealing fuel system components, engineers rely on controlled metering and mixing to achieve predictable results. Understanding how high-pressure and low-pressure dispensing systems behave helps production teams optimize throughput while protecting material quality. This conversation becomes especially relevant when selecting polyurethane processing equipment for aerospace, where material viscosity, cure profile, and application accuracy must align with strict aerospace standards. At the same time, broader trends in polymer processing continue to push manufacturers toward smarter, more adaptable dispensing platforms that support both automation and traceability.

Understanding dispensing architectures in aerospace manufacturing

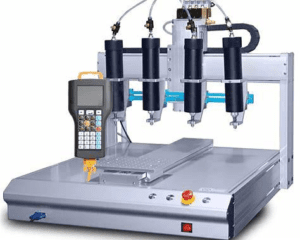

Dispensing systems are generally categorized by how the material is pressurized, mixed, and delivered to the application point. Each architecture offers distinct advantages depending on production volume, material chemistry, and process control requirements.

High-pressure dispensing systems

High-pressure systems use impingement mixing, where two or more components collide at high velocity inside a small mixing chamber. This creates rapid and highly uniform mixing without mechanical agitation. In aerospace production, this approach supports fast cycle times, tight mix ratios, and minimal material residence time, which reduces the risk of premature curing.

High-pressure systems are commonly selected for automated lines, robotic dispensing, and high-volume applications that require consistent bead geometry and predictable cure behavior. When integrated with modern controls and flow monitoring, these platforms deliver repeatable results across large production runs. Many manufacturers evaluating polyurethane processing equipment for aerospace favor high-pressure solutions when precision and throughput must coexist with minimal material waste and stable process windows.

Low-pressure dispensing systems

Low-pressure dispensing relies on mechanical mixing, typically using static or dynamic mixers driven by pumps operating at lower pressures. These systems offer flexibility for smaller batch sizes, frequent material changes, and applications requiring gentle material handling.

Low-pressure platforms are well-suited for prototyping, repair operations, and lower-volume assembly environments. They allow easier flushing, faster material changeover, and simpler maintenance procedures. For specialty formulations or sensitive additives, low-pressure systems provide greater operator control while still maintaining accurate ratio management. Within broader polymer processing workflows, low-pressure dispensing supports customization and agile manufacturing without sacrificing consistency.

Choosing the right mix strategy for aerospace programs

Selecting between high-pressure and low-pressure dispensing is rarely a binary decision. Production volume, automation level, material viscosity, cure speed, environmental control, and quality documentation all influence system selection. High-pressure platforms excel in repeatability and scalability, while low-pressure systems deliver flexibility and operational accessibility.

Engineering teams often evaluate lifecycle cost, integration compatibility, and data capture capabilities when designing dispensing cells. As aerospace programs continue to demand tighter tolerances and increased digital traceability, the intersection of intelligent controls and advanced polymer processing technologies becomes increasingly important. Aligning dispensing architecture with long-term production strategy ensures smoother validation cycles and consistent product performance.

Final perspective on mastering the mix

Mastering dispensing performance requires balancing material behavior, production efficiency, and quality assurance. Whether the application favors impingement mixing or mechanically assisted blending, understanding system behavior empowers manufacturers to optimize reliability and reduce rework. Strategic investment in polyurethane processing equipment for aerospace enables scalable growth while maintaining strict process control. As innovation in polymer processing continues to accelerate, aerospace manufacturers who refine their dispensing strategies gain measurable advantages in consistency, compliance, and operational confidence.