Innovative cable jointing solutions are transforming the connectivity of electrical and data networks, enhancing reliability and efficiency across various applications. From the installation, the technology and construction of cable joints designed for extreme conditions, these advancements ensure durable and long-lasting connections.

Field Installation Techniques

For the electrical engineer or electrician, field installation techniques for high tensile field fences and field gates require careful planning and the right tools to ensure durability and functionality.

High Tensile Field Fence Installation

When installing high tensile field fences, the brace is the backbone of the fence. It is crucial to build strong braces with deep posts and good cross members to ensure the fence’s stability. The Becker Gaucho Pro 1047 field fence, for example, uses 10 wires and stands 47 inches tall. Properly terminating the fence ends with tools like the T-clip from Gripples ensures a secure and lasting installation.

Key steps include:

- Planning the Layout: Consider future uses of the property and plan the fence layout accordingly, including the placement of gates.

- Rolling Out the Wire: Ensure the wire is free from obstructions like roots to prevent distortion.

- Terminating the Ends: Strip the hinge joint knots and use T-clips for secure termination.

- Pulling the Fence: Do not exceed 660 feet when pulling the fence to avoid overstraining. Use pull braces at intervals to maintain tension.

Field Gate Installation

Installing a field gate involves several steps to ensure it functions correctly and remains durable over time.

Hinges and Fittings

Field gates should be fitted with appropriate hinges, latches, and drop bolts. Adjustable double strap field hinge sets are recommended for wooden gates, allowing for adjustments as the gate weathers. The size of the hinge set depends on the gate width:

- Gates 3ft-5ft wide: 12” hinges

- Gates 6ft-10ft wide: 18” hinges

- Gates 10ft+ wide: 24” hinges.

Latches and Drop Bolts

Different latch options are available depending on how the gate is hung:

- Between Posts: Spring fastener set with central closing catch or shoot bolt.

- On the Face of Posts: Self-locking gate latch kit with striker or spring fastener set with staple or drive catch.

- Gates Hung Together: Throw over loops and drop bolts are essential for stability.

Gate Treatment and Storage

Wooden gates should be pressure treated to protect against rot and insects. Additional treatments like Restol UV Oil can enhance protection against sun and moisture. Proper storage before installation is crucial to prevent warping; gates should be laid flat on bearers out of direct sunlight.

Gate Posts

Gate posts should be long enough to provide stability, typically 2.1m long, with at least 760mm in the ground. The post size varies with the gate width:

- Up to 1.83m wide: 150 x 150mm posts

- Up to 3.66m wide: 175 x 175mm posts

- Over 3.05m wide: 200 x 200mm posts.

By following these detailed installation techniques, both high tensile field fences and field gates can be installed effectively, ensuring long-term durability and functionality.

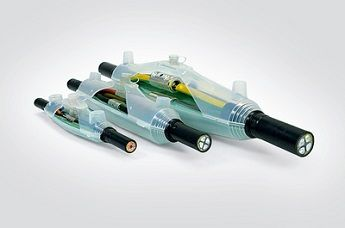

Gel-Filled Cable Joints for Extreme Conditions

Gel-filled cable joints are designed to provide reliable and robust connections under extreme conditions, such as outdoor and underground installations. These joints, like the RELICON Reliseal, feature a polypropylene shell that resists UV light, temperature extremes, and impact, ensuring durability and longevity. They are waterproof and tested to IP68 standards, capable of withstanding water depths up to 10 meters. The gel inside the joints offers mechanical protection and insulation, simplifying installation without the need for special tools. Additionally, these joints include integrated strain relief to protect against tensile forces, making them suitable for various challenging environments.

Innovative Faraday Cage Integration

Innovative Faraday cage integration is transforming various industries by enhancing the protection of sensitive equipment from electromagnetic interference (EMI). Modern Faraday cages are being incorporated into everyday consumer products, such as smartphones and tablets, to shield internal components from external electromagnetic fields. Additionally, advancements in materials and construction methods are improving the effectiveness of these cages, making them more efficient and versatile. The market for Faraday cages is experiencing steady growth, driven by the increasing demand for sustainable and high-performance products, as well as the integration of cutting-edge technologies like artificial intelligence and blockchain to enhance product quality. This trend is expected to continue, with the global Faraday cage market projected to expand significantly by 2030.

Enhanced Durability and Strength

Gel-filled cable joints, such as the RELICON Reliseal, are engineered to offer enhanced durability and strength, making them ideal for demanding environments. The polypropylene shell of these joints is resistant to UV light, temperature extremes, and impact, ensuring long-term performance and reliability. These joints are waterproof and meet the IP68 standard, which means they can withstand water depths of up to 10 meters, providing robust protection against water ingress.

The gel inside the joints not only provides excellent insulation but also offers mechanical protection, which simplifies the installation process by eliminating the need for special tools or accessories. This gel is designed to maintain its properties over time, ensuring that the joint remains effective even under harsh conditions. Additionally, the integrated strain relief in these joints protects the connection from tensile forces, which can occur during installation or due to environmental factors such as soil movement or temperature fluctuations.

These features make gel-filled cable joints particularly suitable for outdoor and underground installations, where they are exposed to various environmental stresses. The robust construction and reliable sealing capabilities of these joints ensure that they can withstand the rigors of such environments, providing a long-lasting and secure connection for electrical cables.

Improved Thermal Insulation

Improved thermal insulation in cable joints is crucial for maintaining the efficiency and safety of electrical systems, particularly in high-load and high-voltage applications. One of the key advancements in this area is the development of a quasi-3D axial thermal model for cable joints, which allows for more accurate thermal analysis and better insulation design. This model takes into account the thermal conductivity of different components, the outer and inner diameters of each layer, and the radial and axial heat fluxes, providing a comprehensive understanding of the thermal behavior of cable joints.

Additionally, the use of forced convection methods, such as applying cooling fans, has been shown to significantly enhance the heat transfer performance of cable joints. By positioning cooling fans at optimal segments of the cable joint and adjusting the air velocity, the thermal rating of the cable joint can be improved, reducing the risk of overheating and electrical accidents. Experimental results indicate that the optimal position for a cooling fan is at segment C1/C2 of the cable joint, with a recommended air velocity of 4 m/s.

Moreover, the integration of advanced materials, such as polyolefin for heat-shrink insulation, further enhances the thermal insulation properties of cable joints. These materials provide excellent mechanical strength, sealing, and impact resistance, ensuring long-term durability and reliability in various environmental conditions. The use of heavy wall heat tubing in these joints also contributes to improved thermal insulation by providing a robust barrier against external thermal influences.

In summary, improved thermal insulation in cable joints is achieved through advanced thermal modeling, the application of forced convection methods, and the use of high-performance materials. These innovations ensure that cable joints can withstand high loads and harsh environmental conditions, maintaining the efficiency and safety of electrical systems.

Electromagnetic Interference Shielding

Electromagnetic interference (EMI) shielding is essential for protecting electronic devices from disruptive electromagnetic fields. EMI shielding involves using conductive or magnetic materials to create barriers that reduce or redirect electromagnetic fields, thereby minimizing interference with electronic components. This shielding is crucial in various applications, including medical, military, aerospace, and consumer electronics, where EMI can cause data loss, system failures, or even endanger lives.

The effectiveness of EMI shielding depends on several factors, including the material used, its thickness, and the frequency of the electromagnetic fields. Common materials for EMI shielding include metals like copper, brass, nickel, silver, steel, and tin, which are selected based on their conductivity, permeability, and other physical properties. For instance, highly conductive metals like copper and silver are effective at reflecting electrically dominant waves, while less conductive metals like steel are better at absorbing magnetically dominant waves.

Practical Applications

In practical applications, EMI shielding can take various forms. For example, shielded cables use a wire mesh surrounding the inner core conductor to prevent signal leakage and external interference. Similarly, the door of a microwave oven incorporates a screen that acts as a Faraday cage, blocking microwaves while allowing visible light to pass through. In more advanced applications, such as military and aerospace, EMI shielding is used to protect critical systems from high-power microwave weapons and other intentional electromagnetic interference (IEMI) threats.

Innovative Materials and Designs

Innovative materials and designs are continually being developed to enhance EMI shielding effectiveness. For instance, graphene-based polymeric composites and other nanocomposites are gaining attention for their unique combination of electrical, magnetic, and mechanical properties, making them highly effective EMI shields. Additionally, flexible metal screens, metal foams, and metallic inks are used to coat electronic enclosures, providing lightweight and adaptable shielding solutions.

One notable advancement is the development of particle-filled silicones, which combine the electrical properties of metals with the flexibility and durability of silicone rubber. These materials are particularly useful in applications requiring both EMI shielding and environmental sealing, such as ruggedized touchscreens and other outdoor electronic devices.

Overall, EMI shielding is a critical aspect of modern electronic design, ensuring the reliable operation of devices in environments with high electromagnetic activity. By selecting appropriate materials and employing innovative designs, engineers can effectively mitigate the risks associated with electromagnetic interference, safeguarding both the functionality and safety of electronic systems.

High-Voltage Performance

High-voltage cable joints are essential for the efficient and safe transmission of electrical power in high-voltage systems. These joints connect multiple cables, ensuring the seamless flow of electricity across long distances and through various environmental conditions. The performance of high-voltage cable joints is influenced by several factors, including the materials used, the design of the joints, and the installation techniques.

Materials and Design

High-voltage cable joints are constructed using advanced materials and technologies to withstand the high voltage, current, and environmental stresses they encounter. These materials include high-strength insulating materials, specialized connectors, and advanced insulation systems. Features such as shielding, grounding, and surge protection are often incorporated to minimize the risk of electrical faults or failures. For instance, 3M Cold Shrink technology is used in some high-voltage cable joints to provide reliable insulation and protection against environmental factors.

Types of High-Voltage Cable Joints

There are various types of high-voltage cable joints, each suited for different applications and voltage levels. Common types include:

- Cold Shrink Joints: These joints use pre-stretched rubber sleeves that shrink upon installation, providing a tight seal and excellent insulation. They are suitable for voltages up to 72.5kV and are used in both inline and crossbond/shield break splicing applications.

- Heat Shrink Joints: These joints involve heat-activated materials that shrink to form a secure and insulated connection. They are commonly used for medium to high-voltage applications, including 11kV to 132kV cables.

- Push-On and Slip-Over Joints: These joints are designed for quick and easy installation, often used in situations where space is limited or where rapid deployment is necessary.

Installation Techniques

Proper installation is crucial for the performance and longevity of high-voltage cable joints. Installation should be carried out by trained and competent jointers following the manufacturer’s instructions. Key steps include ensuring sufficient jointing room, correctly aligning the cables, and using appropriate tools such as hydraulic crimping tools for terminating cable conductors. Safety procedures must be strictly followed to protect workers and equipment, including proper insulation and grounding of all connections.

Performance and Reliability

The reliability and durability of high-voltage cable joints are paramount. These joints must maintain their integrity under extreme conditions, such as high temperatures, moisture, and corrosive environments. By using high-quality materials and adhering to proper installation practices, high-voltage cable joints can minimize the risk of electrical faults and ensure the smooth operation of power systems. For example, the Nexans JTS series offers improved reliability and advanced safety features at reduced costs, making them a popular choice for medium and high-voltage applications.

In summary, high-voltage cable joints are critical components in electrical power systems, designed to ensure safe and efficient power transmission. Their performance is enhanced by the use of advanced materials, proper installation techniques, and adherence to safety standards, ensuring long-term reliability and durability in various environmental conditions.

Summary and Key Points

High-voltage cable joints are critical components in electrical power transmission and distribution systems, connecting multiple cables to ensure the safe and efficient transfer of high-voltage electrical power. These joints must be designed to withstand high voltage, current, and environmental stresses, maintaining their integrity even under adverse conditions such as extreme temperatures, moisture, and corrosive environments.

Key Points:

- Materials and Technologies: High-voltage cable joints are constructed using advanced materials like high-strength insulating materials, specialized connectors, and advanced insulation systems. These materials help the joints withstand high voltage and current, as well as environmental stresses.

- Design Considerations: Important design factors include the types of cables being joined, voltage levels, expected transient overvoltages, number of phases, dielectric strength of interfaces, choice of materials, and location of installation. Proper design ensures good thermal performance, electrical stress control, and environmental and mechanical protection.

- Types of Joints: Common types of high-voltage cable joints include cold shrink joints, heat shrink joints, and push-on/slip-over joints. Each type is suited for different applications and voltage levels, providing reliable insulation and protection against environmental factors.

- Installation Techniques: Proper installation is crucial for the performance and longevity of high-voltage cable joints. Installation should be carried out by trained professionals following strict safety procedures and guidelines to protect workers, equipment, and the surrounding environment.

- Performance and Reliability: High-voltage cable joints must maintain their reliability and durability under extreme conditions. By using high-quality materials and adhering to proper installation practices, these joints can minimize the risk of electrical faults and ensure the smooth operation of power systems.

- Innovative Solutions: Innovations such as the integration of Faraday cages, advanced thermal insulation models, and forced convection methods enhance the performance and reliability of high-voltage cable joints. These advancements address the demands of modern electrical systems and ensure long-term durability.

In summary, high-voltage cable joints are essential for the efficient and safe transmission of electrical power. Their performance is enhanced by advanced materials, proper design and installation techniques, and innovative solutions, ensuring long-term reliability and durability in various environmental conditions.