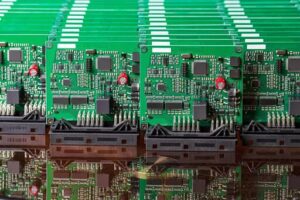

As electronic products become more compact, powerful, and design-driven, the need for advanced circuit board solutions has grown rapidly. Traditional rigid PCBs are no longer sufficient for many modern applications that require flexibility, durability, and efficient use of space. This is where a rigid flex pcb manufacturer and FastTurn PCB services play a crucial role in today’s electronics industry.

Rigid flex PCBs combine the advantages of both rigid and flexible circuit boards into a single structure. When paired with FastTurn PCB manufacturing capabilities, businesses can enjoy both innovative design freedom and rapid production timelines, which are essential in competitive markets such as medical devices, aerospace, automotive electronics, and consumer gadgets.

What is a Rigid Flex PCB?

A rigid flex PCB is a hybrid circuit board that consists of rigid board sections connected by flexible circuit layers. These boards are designed to bend and fold without damaging the circuit, making them ideal for compact devices and complex assemblies.

Unlike traditional PCB assemblies that require connectors, cables, and multiple boards, rigid flex PCBs eliminate extra interconnections. This results in a more reliable, lightweight, and space-efficient solution. The flexible sections allow the board to fit into tight or irregular spaces, while the rigid areas provide strong support for components.

Because of their complexity, these boards require the expertise of an experienced rigid flex PCB manufacturer who understands the materials, layering techniques, and design precision required to ensure performance and durability.

Why Choosing the Right Rigid Flex PCB Manufacturer Matters

Manufacturing rigid flex PCBs is far more complex than producing standard rigid boards. It requires specialised equipment, high-quality materials, and strict quality control processes. Choosing the right rigid flex PCB manufacturer can directly impact the performance and lifespan of your electronic product.

A reliable manufacturer offers:

Advanced Manufacturing Capabilities

Rigid flex PCBs require precise lamination, accurate drilling, and careful alignment of flexible and rigid layers. Experienced manufacturers use advanced machinery to achieve this precision.

Material Expertise

The flexible part of the board uses polyimide materials, while the rigid part typically uses FR-4. A skilled manufacturer knows how to combine these materials effectively without compromising durability.

Design Support

Many rigid flex PCB manufacturers provide engineering support to help optimise designs for manufacturability and performance. This reduces errors and improves product reliability.

Strict Quality Control

Due to the demanding nature of applications like medical and aerospace devices, quality testing is critical. Reputable manufacturers perform electrical testing, impedance control, and stress testing.

Applications of Rigid-Flex PCBs

Rigid flex PCBs are widely used in industries where reliability, compactness, and performance are essential. Common applications include:

- Medical equipment and wearable health devices

- Aerospace and defence electronics are exposed to vibration and temperature changes

- Smartphones, cameras, and tablets with tight internal spaces

- Automotive control modules and sensors

- Industrial automation and robotics

In these applications, the combination of flexibility and strength makes rigid flex PCBs the ideal choice.

What is FastTurn PCB?

While advanced design is important, speed is equally critical in product development. FastTurn PCB refers to rapid PCB prototyping and manufacturing services that deliver boards in a very short time frame, sometimes within 24 to 72 hours.

FastTurn PCB services are especially useful during the product development phase, where engineers need to test and refine designs quickly. Instead of waiting weeks for PCB fabrication, companies can receive prototypes in days, speeding up the entire development cycle.

Benefits of FastTurn PCB Services

Rapid Prototyping

FastTurn PCB allows engineers to move from design to testing quickly. This helps identify design flaws early and make improvements without delays.

Faster Time to Market

Companies that use FastTurn PCB services can launch products more quickly than competitors by shortening development timelines.

Reliable Quality

Despite the quick turnaround, reputable FastTurn PCB providers maintain high manufacturing standards, ensuring accurate and functional prototypes.

Efficient Iteration

When changes are needed, FastTurn services make it easy to revise designs and receive updated boards quickly.

The Advantage of Combining a Rigid Flex PCB Manufacturer with FastTurn PCB

The real advantage comes when a rigid flex PCB manufacturer also offers FastTurn PCB services. This combination allows companies to design complex, space-saving rigid flex boards and receive them rapidly for testing and validation.

For example, a company developing a wearable medical device can design a compact rigid flex PCB and get a prototype within days. This speeds up testing, ensures proper fit inside the device, and reduces development risks.

Industries that benefit greatly from this combination include:

- Medical technology developers needing quick, reliable prototypes

- Aerospace companies require lightweight and durable boards

- Consumer electronics brands designing compact gadgets

- Automotive manufacturers are developing smart control systems

What to Look for in a Manufacturer Offering Both Services

When selecting a provider, consider the following:

- Proven experience as a rigid flex PCB manufacturer

- Capability to handle complex multilayer designs

- FastTurn PCB production timelines without compromising quality

- In-house testing and quality assurance

- Technical support for design optimization

Working with a manufacturer that understands both advanced PCB design and rapid production ensures smoother development and better final products.

Conclusion

The demand for smaller, smarter, and more reliable electronic devices is driving the need for advanced PCB solutions. Partnering with a trusted rigid flex PCB manufacturer ensures that your designs meet high standards of durability and performance. At the same time, FastTurn PCB services enable faster prototyping and reduced time to market.

Together, these capabilities provide businesses with the flexibility to innovate and the speed to compete. Whether you are developing medical equipment, aerospace systems, or next-generation consumer electronics, choosing the right manufacturer with FastTurn capabilities can make a significant difference in your product’s success.