Introduction

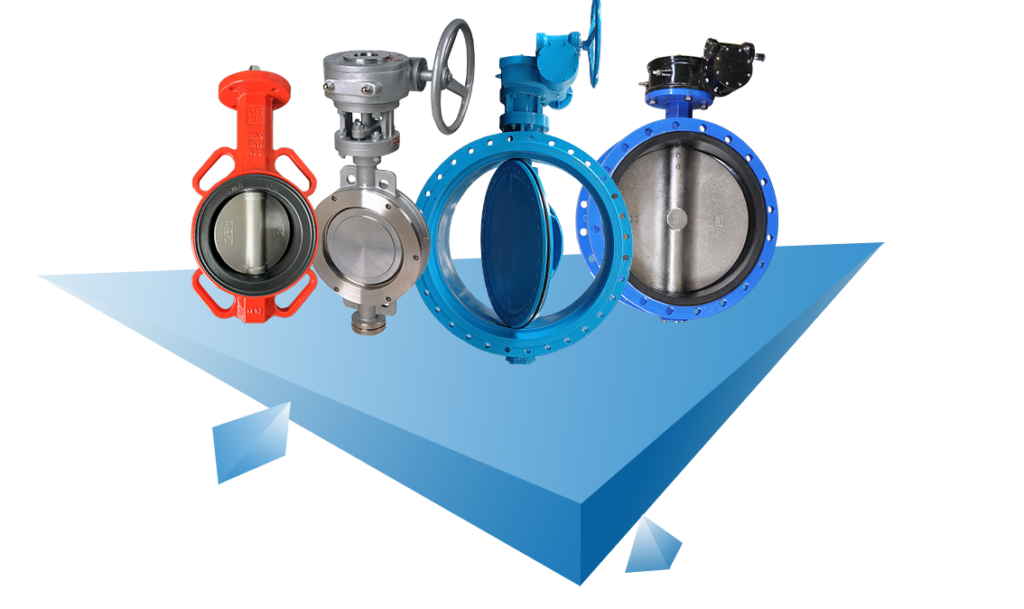

Butterfly valves are quarter-turn valves with the disc mounted on a rod that rotates on its axis. When the valve is shut down, the disc is rotated to seal the flow path to its surroundings. On its turn, the disc rotates 90 degrees to open the valve and provide unobstructed flow through it thoroughly.

People use butterfly valves more than other valves for four main reasons. They cost less, are easy to maintain, keep the flow smooth when open, and seal tightly when closed. Nonetheless, like any other equipment, the pipes can pose problems as they age. Plant technicians should know some key issues that affect butterfly valves and how to solve them. They are helpful when they deal with butterfly valves.

Leakage

The most prevalent difficulty of this type of butterfly valve is that it leaks at close times. This can occur due to a few different reasons: This can occur due to a few different reasons:

Worn Seat

Over time, the rubber seat in the valve body can deteriorate. It comes into contact with the disc and can develop pits. The pits will not allow the seat to hold tightly. This seat will have to be changed. Some of this furniture, such as this seat, must be replaced.

Damaged Disc Edge

The disc’s downside might be nicked or worn off by frequent opening and closing. Then, it will not fit tightly with the rubber seat and will leak. Refinishing or replacing the disc’s outer rim may be necessary.

Stem Packing

Seal features are located where the stem comes out of the valve body, and packing helps reduce leaks at this location. It must be replaced if it gets worn over the years and the stem packing becomes cracked or compressed.

Loose Packing Gland

The gland nut grips the stem, packing firmly with the stem. It is designed so that if this nut becomes loose over time, the packing may shift and cause leaking around the stem. In many cases, simply tightening the nut will rectify the problem.

More information is available on fixing valve leaks.

Torque or Difficult to Unlock and Re-lock

This is because butterfly valves are expected to open or close with the most negligible torque needed on the operator handle or actuator. However, if the shafts are not greased up adequately or due to some internal friction and wear, the torque rises significantly. Issues include:

Insufficient Lubrication

Lubricate the faces of the valve disc and seats from time to time. This reduces the chances of both galling and corrosion, as well as the friction at the interface. Another aspect that must be considered is the greasing of the stem bushings/bearings. Lubrication needs are likely to increase to solve high torque problems experienced in the machines.

Damaged Internal Components

Eventually, the edges of the disc, stem, or other metal parts of the fastener will come out of the proper fit. Some parts may need to be replaced to ensure that operations are not strained again as they were in the beginning. Always scrutinize the parts. Carefully examine them when the valve is removed or dismantled.

Distorted Body

Any undue pressure on the mount or wearing down of this valve body may lead to distortion. The alignment of the body, bolts, and valve assembly must be inspected. If the body itself of such notions has become twisted or warped, then replacement may be necessary.

External Obstructions

It can be stiff. The stiffness can be due to the buildup of process material, air/water pressure imbalances, or other forces. These forces can hinder its opening/closing. This is as external factors affecting learning, and as Harding pointed out, it is crucial to note and fix these.

Further details about high torque issues of butterfly valves Learn more.

I can only think of one: Being unable to open or close the door entirely.

One leading issue people face is when the butterfly valve appears to be partially opened or partially closed. Some potential causes include:

Disc Not Rotating

The edge of the disc, stem, or internal parts have worn or corroded. They are no longer smooth. So, the disc cannot fully open or close. Repairing it or replacing it on the inside is sometimes required.

Actuator Failure

Problems with the valve handle, the lever, or the automated feature can mean that the valve cannot open right to the end or shut right to the end. The cables, power supply, airlines, and all related components connected to the actuator should be checked for damage. Sometimes, adjusting or repairing the actuator is only necessary, and this could take care of the issue.

[Find out more] about butterfly valve actuators and the way they operate.

Obstructed Material

The amassment of process material near the seat and seals can mechanically preclude the disc from going into the fully closed or fully opened positions. The solution is simple, that is, removing the combination obstruction.

Bent Stem

For instance, if the valve stem has been bent by piping stress or other force, then the rotation of the disc will be significantly affected. Depending on how much the patient wishes to regain their full motion, the stem may require some sort of refurbishment or even replacement.

Noisy Operation

While butterfly valves typically operate quietly, loud noise during operation or vibration/chatter can indicate problems such as: While butterfly valves typically operate quietly, loud noise during operation or vibration/chatter can indicate issues such as:

Cavitation Damage

A leading cause of flow conditions inside the valve can be the formation of vapor bubbles that collapse and cause harm through cavitation. This, in turn, calls for recognition and rectification of the actual flow configuration that leads to cavitation.

Galling/Scoring

As stated, high torque problems, lack of lubrication, or deterioration of its components through rusting or corrosion may make the disc, stem, and seat surfaces abrasive and adjoin each other during use, thus producing noise and vibration. Subsequently, repairing or, in some cases, entirely changing the elements that are worn out is vital.

Loose Components

Any attached bolts, discs, seats, stems, or other internal parts that have become loosened to an extent can shake or vibrate abnormally during the operation. To solve this problem, loose parts and other damaged components should be tightened or replaced.

Conclusion

Butterfly valves, as mentioned, are primarily self-operating valves that require very little maintenance. Usually, the following operating problems arise in butterfly valves. Knowledge of typical repair interventions, including servicing worn seats and seals, correcting mechanical actuator issues, eliminating obstructions, straightening bent stems, applying more lubricants, securing loose parts, or replacing broken parts, can aid plant personnel in addressing butterfly valves and getting operational with less delay. It is also equally essential to maintain the system through early preventive measures to eliminate operation issues and enhance service duration. Plant engineers, mechanics, and maintenance teams should always collaborate to address butterfly valve problems as they arise and fix them as fast as expected.