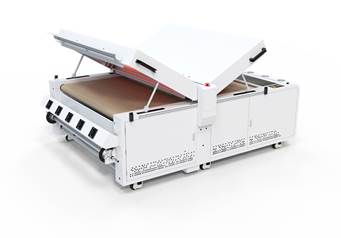

SUBLISTAR DTF powder shaker machine, as one of the overall core of DTF printing, has a certain brand reputation in the DTF printing industry with its excellent technical performance and reliable product quality. This paper will analyze the competitive advantages of SUBLISTAR DTF powder shaker machine in detail from multiple dimensions such as technological innovation, performance parameters, economic benefits, quality control and after-sales service.

1. Technological innovation

SUBLISTAR has a professional technical research and development team, always adhere to the front line, to meet the diversified and convenient production needs of customers.

(1) Efficient oven system:

Preheating powder silo + white smooth coating: The preheating powder silo can effectively ensure the smooth flow of hot melt powder in low temperature or slightly wet environment, and the white smooth coating ensures the powder is smoother and effectively prevents powder accumulation. Make the hot melt powder more efficient work, a small amount of caking can also work smoothly and effectively.

Dual oven configuration is optional, according to the size of the DTF printer reasonable selection. Small printer size, no need for double oven. If the printer size is greater than 600mm and the number of nozzles is greater than 3, you can consider choosing a double oven. And the temperature in the oven can be adjusted to match the temperature required for drying the film, and the effect is better.

Automatic powder return function: increase powder partition, minimize powder leakage, reduce the frequency of manual powder return. Recycle hot melt powder.

High powder shaking efficiency: the vibration frequency can reach 3000 times/minute, and the amplitude is accurately controlled in the range of 0.5-2mm. The unique vibration mode design ensures that the height of the hot melt powder is integrated with the pattern, far exceeding the industry average of 95%. Vibration motor adopts precision imported parts, and its service life is 2 times that of ordinary motors.

(2) Intelligent control system

Intelligent touch screen: Industrial grade 7 inch PLC color screen, support multi-language, the operation steps are clearer, simpler, higher specifications, better experience.

Intelligent linkage: With the printer and cutting machine and computer linkage, with real-time monitoring function, oven temperature is too high or too low, timely remind the staff to adjust, to ensure the best state of drying and curing. Remote control and software upgrades are supported to ensure optimal performance at all times.

CE certification: After professional certification, in strict accordance with the standard implementation, rest assured to choose SUBLISTAR brand.

(3) Green environmental protection

Equipped with a built-in purifier, effective smoke removal, the purifier can effectively filter some gases and odors, to avoid the operator in the daily work process to inhale too much spilt dust.

High efficiency and energy saving: the oven reserves space for heating pipes, and the number of heating pipes can be increased according to actual needs. Avoid excessive or insufficient drying temperature caused by too many or too few heating tubes. Energy consumption relative to other brands and old models, has been upgraded and updated, more power saving. Noise reduction is also carried out as far as possible to avoid excessive operating noise.

(4) Humanistic care

The cooling fan mouth is equipped with an anti-entanglement protective cover —— to prevent hair, clothing, etc., from being sucked in, especially for women workers to collect printed film and protect personnel safe operation.

Add baffles to ensure that the paper is received neatly, clamping rods, and replaceable rollers to meet the paper receiving of coil and sheet paper.

Add oil discharge hole and waste oil alarm, quick oil discharge, no oil accumulation, keep the machine clean. When the waste oil reaches the limit level, the alarm will remind us to deal with it.

The lifting ring is installed to facilitate the movement of heavy equipment, and the box is opened with one key. The door is convenient to open and easy to maintain.

Prevent leakage caused by power failure or voltage instability, protect equipment circuit and personnel safety.

2. Economic benefit advantage

(1) Improved production efficiency

Single SUBLISTAR DTF powder shaker machine production equipment combined with cutting machine and multi-station heat press, the daily production efficiency can exceed 30% of peers at least. The greater the number of production, the less time, can better meet the needs of large customers.

(2) Reduced operating costs

The consumables used are more economical, the energy consumption is reduced, and one person can manage multiple machines, saving labor costs. And DTF powder shaker and DTF printer have intelligent management system, more time and labor saving.

(3) High return on investment

DTF printing supports personalized customization, the output color is bright, restore the design required by customers, and achieve higher added value of the output.

3. Performance advantage

Choose any brand of printer can not avoid a variety of problems, nothing more than the size of the problem, how much, the length of time. Even the industry benchmark EPSON, Roland, etc., may make you at a loss. SUBLISTAR DTF powder shaker machine is produced in strict accordance with the highest standards, and the product qualification rate is guaranteed.

4. After-sales service is guaranteed

(1) Developed service network system

SUBLISTAR has agents all over the world who can help customers service and solve problems close by. SUBLISTAR’s technical team regularly visits agents in various countries to receive advice and provide technical training. There are video tutorials on multiple social media sites.

(2) Perfect pre-sale and after-sale service

In dealing with customer problems, timely and positive reply, to meet all reasonable needs of customers as far as possible. The machine accessories are guaranteed after sale, the whole machine has a 2-year warranty, the core components have a 5-year warranty, and lifelong technical service.

SUBLISTAR DTF powder shaker machine provides an efficient and environmentally friendly solution for the DTF printing industry with its superior technical innovation and reliable performance. The equipment not only significantly improves production efficiency and product quality, but also significantly reduces operating costs, making it an ideal choice for DTF printing companies. With the continuous innovation of technology and the continuous improvement of service system, SUBLISTAR will continue to develop in the industry and create greater value for users.