Understanding Surface-Mount Technology (SMT) and Its Impact on Electronics

Surface-Mount Technology (SMT) is a critical innovation in the field of electronics manufacturing, revolutionizing the way components are integrated into printed circuit boards (PCBs). By allowing components to be mounted directly onto the surface of a PCB rather than through holes, SMT has significantly transformed the landscape of electronic design and assembly.

The Evolution of SMT

Historically, through-hole technology was the standard method for mounting components onto PCBs. This process involved drilling holes in the board, inserting the leads of components, and soldering them from the underside. While effective, this method was limited by the physical size of the components and the complexity of the assembly process. As electronic devices became more compact and complex, the need for a more efficient assembly method became apparent.

SMT emerged in the 1960s and gained widespread adoption in the 1980s, driven by advancements in automation and the growing demand for smaller, more efficient devices. Today, SMT is the predominant method used in the production of a wide array of electronic devices, from consumer gadgets to sophisticated industrial systems.

Advantages of SMT

One of the most significant benefits of SMT is its ability to save space on PCBs. SMT components are generally much smaller than their through-hole counterparts, allowing for a higher density of components. This compact design is essential for modern electronic devices, which often require multiple functionalities in a limited footprint. For example, smartphones, tablets, and wearable devices utilize SMT to pack advanced technology into slim profiles.

In addition to space savings, SMT enhances the reliability of solder joints. The use of solder paste, which is applied directly to the PCB pads, allows for better control over the soldering process. This leads to more consistent and reliable connections compared to traditional soldering methods, which can be more prone to defects.

The automation of SMT assembly processes also results in increased production efficiency. Automated pick-and-place machines can place thousands of components per hour, dramatically speeding up manufacturing times. This efficiency translates into lower production costs, making electronics more affordable for consumers.

The SMT Assembly Process

The SMT assembly process involves several key steps that ensure components are correctly mounted and soldered to the PCB:

- Solder Paste Application: A stencil is used to apply solder paste to the pads on the PCB. The paste consists of tiny solder particles mixed with flux, which helps the solder flow during the heating process.

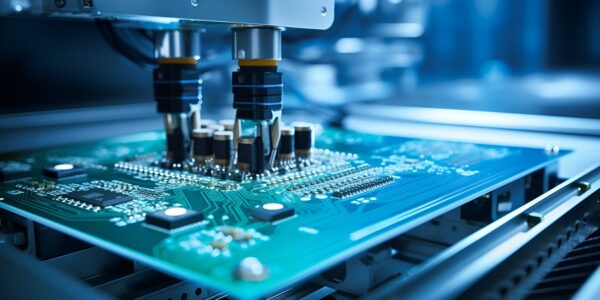

- Component Placement: Automated machines pick up SMT components and place them accurately onto the solder paste-covered pads. This precision is crucial for ensuring proper connections.

- Reflow Soldering: The PCB is then passed through a reflow oven, where the solder paste is heated to its melting point. As the solder melts, it forms strong connections between the components and the PCB.

- Inspection: After soldering, the assembly is inspected using Automated Optical Inspection (AOI) systems. These systems detect defects such as misaligned components or insufficient solder, ensuring high quality in the final product.

- Functional Testing: The final step involves testing the assembled PCB to verify its functionality. This ensures that all components are working as intended and that the device meets required specifications.

Applications of SMT

SMT is widely utilized across various industries due to its numerous advantages. In consumer electronics, SMT allows for the creation of compact devices that can offer advanced features without sacrificing portability. The automotive industry leverages SMT for the development of sophisticated electronic systems that enhance safety, navigation, and communication in vehicles.

Moreover, SMT is crucial in the medical field, where compact and reliable devices are essential. From portable diagnostic tools to complex monitoring systems, SMT enables the integration of advanced technologies in small, user-friendly formats.

Challenges in SMT

Despite its many benefits, SMT is not without challenges. The smaller size of SMT components can complicate handling and assembly, requiring specialized equipment and trained personnel. Additionally, thermal management becomes critical in densely populated boards, as components can generate significant heat during operation.

Quality control is another vital aspect of SMT. The potential for defects such as solder bridging or insufficient solder means that manufacturers must implement rigorous testing and inspection protocols to ensure product reliability.

The Future of SMT

As technology continues to advance, the future of SMT looks promising. Trends such as the Internet of Things (IoT) and 5G technology are driving the demand for more sophisticated electronic devices. SMT will play a crucial role in accommodating the increasing complexity and miniaturization of these products.

In conclusion, Surface-Mount Technology has fundamentally changed the electronics manufacturing landscape. Its ability to provide compact designs, enhance reliability, and streamline production processes makes it an indispensable component of modern electronics. As innovations continue to unfold, SMT will remain at the forefront of electronic design and manufacturing, enabling the development of the next generation of smart, efficient devices.