Robotics in DIY workshops is making hobby projects more exciting. Builders can now create machines that move, sense, and respond to their surroundings. Simple kits are still useful, but more advanced projects are possible at home.

Learning basic programming adds a new level of challenge and fun. Access to tools and parts is easier than ever before. Robotics in DIY workshops teaches problem-solving and planning skills.

Start with small projects and build confidence as skills grow. Explore these ideas to make your next project smarter and more interactive.

Understanding Robotics Basics

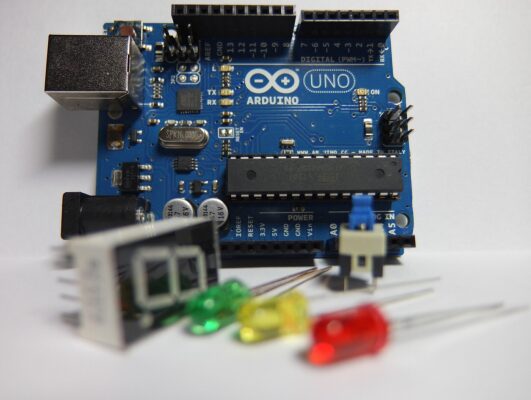

Robotics starts with understanding basic components. Motors, sensors, and controllers are the main parts. Each part works together to make the robot move and act. Beginners should try small projects first. Testing parts one by one helps avoid mistakes later.

Knowing basic circuits makes projects safer and easier. Even simple robots teach important engineering skills. Combining mechanical and electronic elements makes projects more interesting. Practicing basics prepares you for bigger and more complex builds.

Choosing the Right Tools

The right tools make a big difference in robotics projects. Screwdrivers, pliers, and wire cutters are essential. A multimeter helps check circuits and fix problems. A small soldering station keeps connections secure. Power tools may be needed for bigger frames.

Keeping tools organized saves time and avoids accidents. Investing in quality tools reduces frustration. Using tools correctly prevents damage to parts. Knowing how each tool works makes building faster and easier.

Planning Your Project

Good planning helps projects go smoothly. Start by sketching your ideas. Make a list of all the parts you need. Break the project into smaller steps. Think about how much space and time you need.

Include testing and adjustments in your plan. Planning reduces mistakes and keeps you safe. Small projects need planning too. Reviewing your plan before starting avoids delays.

Selecting Components

Choosing the right components is very important. Motors should fit the type of movement you want. Sensors must match the task, like detecting obstacles. Controllers need to handle all the parts correctly.

Quality components last longer and fail less. Standard sizes make future upgrades easier. Some parts can be reused for other projects. Using the right robotic parts makes custom builds possible. Good choices save time and materials.

Building Mechanical Structures

Mechanical structures support the robot’s movements. Frames should be strong but lightweight. Joints and mounts must be secure. Balance helps robots move better.

Measuring and cutting accurately makes assembly easier. Test the frame before adding electronics. Replace weak parts for longer life. Simple mechanical designs teach engineering ideas. A strong frame makes the robot more reliable.

Wiring and Electronics

Wiring connects all the robot parts. Follow diagrams carefully. Keep wires neat to prevent shorts. Double-check connections before turning it on. Use safe voltages to protect components.

Electronics should not touch moving parts. Test circuits step by step to find mistakes early. Label wires for easier troubleshooting. Good wiring improves performance and reduces frustration.

Programming Your Robot

Programming gives the robot instructions. Start with simple commands for movement or sensing. Test small sections of code before running the full program. Loops and conditions create more complex behavior.

Clear and organized code is easier to fix. Programming adds creativity to building. Trying different commands helps you learn faster. Logic skills from coding help in other projects. Testing code successfully builds confidence.

Troubleshooting Common Issues

Robots often have small problems. Check connections first. Make sure the power source works. Sensors must be correctly aligned. Review code for mistakes.

Tighten or adjust mechanical parts if needed. Keep notes on fixes. Step-by-step troubleshooting avoids frustration. Learning from mistakes improves skills for the next project.

Adding Sensors and Automation

Sensors let robots react to their environment. They can detect obstacles or measure light. Using more than one sensor allows complex behavior. Automation tasks teach engineering principles.

Test each sensor to make sure it works. Placement affects performance. Coding sensor responses improves robot actions. Sensors increase the robot’s usefulness. Well-integrated sensors make robots feel smart and responsive.

Experimenting with Robotics Projects

Experimenting is part of learning. Try new combinations of motors, sensors, and code. Mistakes teach lessons for later. Adjusting designs improves function and appearance. Sharing experiments inspires new ideas.

Keep a record of what works and what does not. Test limits to learn problem-solving. Experimenting makes building more fun. Continual practice grows skills over time.

Using Modular Components

Modular parts make building easier. Kits have interchangeable pieces for different projects. Modular designs save assembly time and reduce errors. You can combine mechanical, electronic, and sensor modules. Beginners learn one module at a time.

Experienced builders mix modules for advanced projects. Using robotic parts allows more modular experimentation. Modularity encourages creativity and repeated use. Modular builds keep your workshop flexible and ready for new ideas.

Exploring Advanced Features

Advanced features make robots more capable. Wireless control allows remote operation. Adding cameras or extra sensors expands what robots can do. Complex programming makes behavior more interesting.

Energy-efficient design extends run time. Combining mechanical, electronic, and software skills is key. Experimenting with new features teaches more advanced concepts. Upgrading projects keeps learning ongoing. Each new feature adds more function and challenge.

Integrating Robotics with Everyday Tasks

Robots in DIY workshops can help with simple tasks at home. They can move objects, turn on lights, or follow paths. Adding automation makes daily chores easier to manage. Testing each task ensures the robot works reliably. Small adjustments can improve accuracy and efficiency.

Combining sensors and programming allows the robot to respond to changes. Using robotic parts carefully keeps builds safe and effective. Experimenting with everyday tasks teaches practical problem-solving. Integrating robots into simple routines makes projects more useful and fun.

You Must Learn Robotics in DIY Workshops

Robotics in DIY workshops offers endless possibilities. Small projects can grow into automated machines. Learning mechanical, electronic, and programming skills builds practical knowledge. Planning, testing, and experimenting teaches problem-solving.

Modular and flexible parts make repeated projects easier. Both beginners and experienced hobbyists benefit from robotics. Start simple, expand ideas, and see how robotics can improve your workshop. Engaging with robotics makes building more fun and rewarding.

Should you wish to read more, visit our blog page. We’ve got other topics!